NSK ball screw support bearing 30TAC62B SUC10PN7B lead screw bearings

NSK ball screw support bearing 30TAC62B SUC10PN7B lead screw bearings CNC machine tool spindle bearing belong to angular contact ball bearings.Every end-user who uses NSK cnc cutting machine bearing 30TAC62B SUC10PN7B all knows it's high-precision bearing,and widely used in machine tools.This kind of bearings are very durable and can be used in many ways,such as face to face,back to back and face to back.Generally,the accuracy class for 30TAC62B SUC10PN7B is P4/P5.Compare to standard angular contact ball bearings, ball screw bearings have longer life and better reliability.They are much smaller but can support heavier load rating,rely on their best design for among all ball bearings.

Adapt to CNC Machines below :

cnc machine

cnc milling machine

cnc router machine

cnc plasma cutting machine

cnc laser cutting machine

cnc lathe machine

cnc cutting machine

cnc engraving machine

cnc wood carving machine

cnc machine tool

cnc drilling machine

cnc bending machine

cnc wire cutting machine

cnc punching machine

cnc foam cutting machine

cnc router metal cutting machine

cnc turning machine

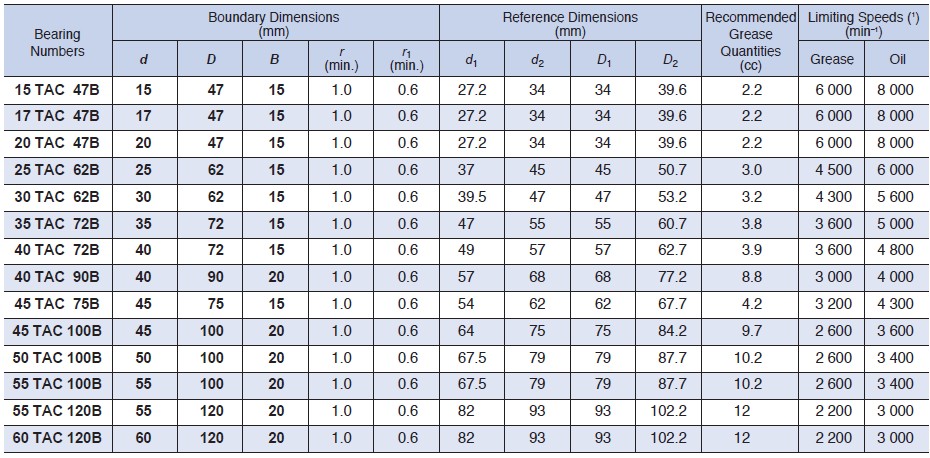

| Commodity name | NSK ball screw support Angular contact thrust ball bearing |

| Bearing model | bearing 30TAC62B SUC10PN7B |

| Bearing specification | 30*62*15 mm bearing |

| Weight /KG | 0.224 KG |

| Bearing Series |

TAC series |

| Ring Materical | Chrome Steel |

| Quality standard | ISO9001:2008 |

| Bearing Precision | P5 ,P4 |

| Main use | machine tool |

| Service | OEM service offer |

|

17TAC47BSUC10PN7B |

17*47*15 |

35TAC72BSUC10PN7B |

35*72*15 |

|

20TAC47BSUC10PN7B |

20*47*15 |

40TAC72BSUC10PN7B |

40*72*15 |

|

25TAC62BSUC10PN7B |

25*62*15 |

40TAC90BSUC10PN7B |

40*90*20 |

|

30TAC62BSUC10PN7B |

30*62*15 |

45TAC75BSUC10PN7B |

45*75*15 |

|

110TAC20X+L |

110*170*72 |

130TAC20X+L |

130*200*84 |

|

120TAC29X+L |

120*165*54 |

140TAC29D+L |

140*190*60 |

|

120TAC20X+L |

120*180*72 |

140TAC20D+L |

140*210*84 |

|

130TAC29X+L |

130*180*60 |

150TAC29D+L |

150*210*72 |

|

45TAC100BSUC10PN7B |

45*100*20 |

150TAC20D+L |

150*225*90 |

|

50TAC100BSUC10PN7B |

50*100*20 |

160TAC29D+L |

160*220*72 |

|

55TAC100BSUC10PN7B |

55*100*20 |

160TAC20D+L |

160*240*96 |

|

55TAC120BSUC10PN7B |

55*120*20 |

170TAC29D+L |

170*230*72 |

|

60TAC120BSUC10PN7B |

60*120*20 |

170TAC20D+L |

170*260*108 |

|

30TAC20X+L |

30*62*34 |

180TAC29D+L |

180*250*84 |

|

40TAC20X+L |

40*68*36 |

180TAC20D+L |

180*280*120 |

|

45TAC20X+L |

45*75*38 |

190TAC29D+L |

190*260*84 |

|

50TAC20X+L |

50*80*38 |

190TAC20D+L |

190*290*120 |

7000 Series spindle bearings series models reference :

7000CTYNSULP4,7000CTYNDULP4,7000CTYNDBLP4,7000CTYNDBLP5,7001CTYNP5,7001CTYNDBLP5,7001CTYNDULP4

7002CTYNDULP4,7002CTYNSULP4,7002CTYNDBLP5,7002CTYNSULP5,7003CTYNSULP4,7003CTYNDULP4,7003CTYNDBLP5

7003CTYNSULP5,7004CTYNSULP4,7004CTYNDULP4,7004CTYNDULP5,7004CTYNDBLP4,7004CTYNDBLP5,7004CTYNSULP5

7005CTYNDULP4,7005CTYNSULP4,7005CTYNDBLP5,7005CTYNSULP5,7006CTYNSULP4,7006CTYNDULP4,7006CTYNDBLP5,

7006CTYNSULP5,7007CTYNSULP4,7007CTYNDBLP5,7007CTYNDULP4,7007A5TYNSULP4,7008CTYNDBLP5,7008CTYNSULP5,

7008CTYNSULP4,7008CTYNDULP4,7008A5TYNDULP4,7009CTYNDULP4,7009CTYNSULP4,7009CTYNDBLP5,7009CTYNSULP5

7010CTYNSULP4,7010CTYNDULP4,7010CTYNDBLP5,7010CTYNSULP5,7010A5TYNSULP4,7011CTYNDULP4,7011CTYNSULP4

7011A5TYNSULP4,7011CTYNSULP5,7012CTYNDULP4,7012CTYNDBLP4,7012CTYNSULP4,7012CTYNSULP5,7012CTYNDBLP5

7013CTYNSULP4,7013A5TYNSULP4,7013CTYNDULP4,7013CTYNSULP5,7014CTYNSULP4,7014CTYNDULP4,7014A5TYNSULP4

7015CTYNDBLP4,7015CTYNDULP4,7015CTYNSULP4,7015CTYNDBLP5,7016CTYNSULP4,7016CTYNDULP4,7017CTYNSULP4,

7017CTYNDULP4,7018CTYNDULP4,7018CTYNSULP4,7019CTYNSULP4,7020CTYNSULP4,7020CTYNDULP4,7021CTYNSULP4,

7022CTYNSULP4,7024CTYNSULP4,7200CTYNSULP4,7200CTYNDULP4,7201CTYNDULP4,7201CTYNDBLP5,7202CTYNSULP4,

7202CTYNDULP4,7202CTYNDBLP5,7202CTYNSULP5,7203CTYNDBLP5,7203CTYNSULP5,7203CTYNDULP4,7203CTYNSULP4,

7204CTYNSULP4,7204CTYNSULP5,7204CTYNDULP4,7204CTYNDBLP5,7204CTYNDBLP4,7205CTYNSULP5,7205CTYNDBLP5,

7205CTYNDULP4,7205CTYNSULP4,7206CTYNDULP4,7206CTYNSULP4,7206CTYNDBLP4,7206CTYNDBLP5,7206CTYNSULP5

7207CTYNSULP4,7207CTYNDULP4,7207CTYNDBLP5,7207CTYNSULP5,7208CTYNSULP4,7208CTYNDBLP4,7208CTYNDULP4

7208CTYNDBLP5,7208CTYNSULP5,7209CTYNSULP4,7209CTYNDBLP5,7209CTYNDULP4,7209CTYNSULP5,7210CTYNDULP4,

7210CTYNSULP4,7210CTYNDBLP5,7210CTYNSULP5,7211CTYNSULP4,7211CTYNDULP4,7212CTYNDULP4,7212CTYNSULP4,

7213CTYNSULP4,7214CTYNSULP4,7215CTYNSULP4,7216CTYNSULP4

NSK bearing knowledge introduction :

NSK precision bearing series numbering system .

Method of cleaning for high precision NSK machine tool bearings :

1,use Kerosene or light oil to clean the bearings.

2,use separate tanks for first cleaning and final cleaning .Each tank should be equipped with a wire rack to

prevent direct contact of the bearing with any contamination that may have settled at the bottom .

3,In the first cleaning tank(B), avoid rotating the bearings.After cleaning the out surfaces with a soft brush,

move the bearings to the final cleaning tank .

4,In the final cleaning tank(C),rotate the bearing by hand very gently .Make sure that the cleaning fluid in the

final cleaning tank is kept clean .

5,Remove excess cleaning fluid from the bearing after cleaning .Allow the bearing to completely dry before

applying grease or oil using a lint free cloth.

6,Bearing using ordinary grease lubrication need to be packed with grease before leaving open to the

environment since the metal surfaces will be vulnerable to corrosion at this stage.(D)

7,Oil lubricated bearings should be mounted on the machine tool taking care not to rotate the bearing.Prior to mounting it is recommended to lightly coat the inner and outer surfaces with a clean light film of oil to assist

mounting .(E)

Packing of NSK CNC machine tool spindle bearings precision bearings :

1):Inner Plastic Bag+ Paper Box + Carton(+Pallet);

2):Big sizes:Wooden Case